Your professional partner for engineering services

We offer a comprehensive service in various areas. These include e.g. the DAkkS calibration of material testing machines and force-proving instruments. Furthermore, we perform testing, third party surveillance and certification (PÜZ) of bearing and expansion joints in structural engineering. Our range is complemented by the testing and certification of personal protective equipment as well as the operation of a crash system for passive safety components.

The Units in our Department

-

Calibration

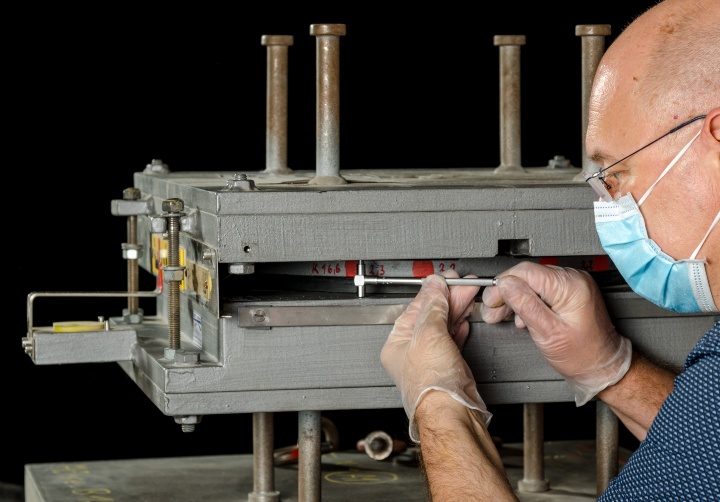

As an independent calibration laboratory we offer the DAkkS calibration of material testing machines and force-proving instruments. With more than 50,000 calibrations under the accreditation, the MPA has a lot of experience. The customer satisfaction is shown by existing customer relationships for more than 50 years. We are in leading positions in the respective committees.

-

Bearing and Expansion Joints in Structural Engineering

Our experts offer the testing, third party surveillance and certification (PÜZ) of bridge bearings, expansions joints and anti-seismic devices. This includes the examination, qualification, quality assurance of bearings and components for bridges and building construction. We are an officially approved and notified inspection and certification body at national and European level. We also carry out courses for the bearing installation.

-

Passive Safety

We perform testing and certification of personal protective equipment (PPE) e.g. bicycle helmets or mountaineering helmets. We also offer testing of seat belts and seat belt systems (including airbags). The exam will be i.a. used for appoval tests at Kraftfahrt-Bundesamt (KBA). Our spectrum is supplemented by the assessment of the crash behavior, e.g. of cargo securing, roof racks or vehicle interior equipment.

Tasks and technical focus

Our department offers a comprehensive range of services. Inform yourself here about the services offered by us or contact us by phone or email!

- DAkkS calibration of force-proving instruments in the range from 100 N to 1 MN. The calibration machines are traceable to the national standard of the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig

- DAkkS calibration / verification of material testing machines including length measuring systems, hardness testing machines, impact testing machines

- DAkkS calibration of the voltage range for amplifiers

- DAkkS calibration of indenters for hardness measurements

- Research and approval tests to prove the applicability of materials and lubricants (components) of bridges and building constructions during short and long term tests in dependence on relevant loading parameters (such as pressure, temperature, velocity) as to friction, wear, creep

- Acceptance tests on bearing components according to the required approval tests and standards as to materials characteristics (strength, hardness), surface characteristics, friction and wear behaviour

- Training of experts in bearings in structural engineering

- Advice on processes in expansion joints in structural engineering

- Type approval tests for safety-belts / restraint systems according to ECE-R 16 / VSTD 26

- Type approval tests for child restraint systems according to ECE-R44

- Type approval tests for motorcycle helmets according to ECE-R22

- Assessment of the crash behaviour for cargo securing according to DIN ISO 27955 and DIN ISO 27956

- Assessment of the crash behaviour for roof racks for passenger cars according to DIN 75302

- Assessment of the crash behaviour for general tests on the dynamic sledge, e.g. holders / components in vehicles, according to customer specification

- Testing of personal protective equipment (PPE) such as helmets for cyclists, equestrian helmets, mountaineering helmets, helmets for skiers or motorcycle helmets

As an officially approved as well as notified inspection and certification body our department offers a comprehensive range of services. Inform yourself here about the services offered by us or contact us by phone or email

- Third party surveillance and certification of bearing systems such as slide bearings, spherical bearings, pot bearings, roller bearings, restrained bearings and approval of components

- Third party surveillance and certification of bridge expansion joints according European Technical Approval Guidelines (ETAGs)

- Third party surveillance and certification of anti-seismic devices according EN 15129

- Certification of personal protective equipment (PPE) such as helmets for cyclists, equestrian helmets, mountaineering helmets, helmets for skiers or motorcycle helmets.

We offer expert activities in different areas. Inform yourself here about the services offered by us or contact us by phone or email!

- Expert activities in expansion joints in structural engineering

- Analysis of events of damage and assessment of the installation situation in the construction, investigation of dismantled bearings

In addition to our portfolio, the topic of research is also active.

- Currently, we are participating in a project (EMPIR, 18SIB08 ComTraForce) involving mainly metrology institutes. This is about the comprehensive traceability for force metrology services. The term is three years.

Bearings for bridges and buildings are safety-relevant components. Bridge bearings need to be designed and produced therefore in Germany according to national technical approvals and national standards. In the courses design and performance features of bearing types, valid regulations, the quality assurance, proper transport and installation in the building structure in theory and practice are conveyed i.a. Depending on the type of course the in lectures mediated content is supplemented and deepened by practical exercises and experimental demonstrations. Inform yourself here about the course offered by us or contact us by phone or email!

- Course A: The five-day bearing installation course with examination serves the acquisition of a temporary 5-year qualification for installation of bearings in bridge and building construction, the successful completion is confirmed by a certificate.

- Course B: The two-day bearing installation course without examination serves the acquisition of knowledge of the installation and installation check for bearings in bridge and building construction.

- Course C: The two-day refresher course is designed for the extension of the in Course A acquired qualification for another 5 years.

The current dates can be found here

Leaflet "Experts for Bearings in Structural Engineering"

Admission requirements for attendance

In committees and working groups we are partly actively involved as chairman or chairperson.

- Chairman of DKD technical committee "Material Testing Machines"

- DKD technical committee "Force and Acceleration"

- Managing-committee of Deutscher Kalibrierdienst

- Chairman of DIN committee NA 062-08-11 AA (NMP 811) "Material Testing Machine"

- DIN committee NA 062-01-44 AA (NMP 144) "Impact Strength Testing on Metal"

- DIN committee NA 062-01-41 AA (NMP 141) "Hardness Testing on Metal"

- VMPA working group "Material Testing Machines and Testing Apparatus"

- Expert committee "Bearing" - A - (411), "Pot Bearing" - B1 - (411a), "Elastomeric Bearing" - B2 - (411b), "Sliding Bearing" - B3 - (411c), "Elastic Elements for Building Support System" - B4 - (411d) of Deutsches Institut für Bautechnik (DIBt), Berlin

- Expert committee "Expansion Joints" - A - (454) of Deutsches Institut für Bautechnik (DIBt), Berlin

- DIN committee NA 005-57-02 (NABau) "Structural Bearing"

How to find us

- Our location on campus

Pfaffenwaldring 32, 70569 Stuttgart - Open Street Map

Contact

Siegfried Gerber

Dipl.-Ing.Head of Department

Andreas Sülzle

Dipl.-Ing.Deputy Head of Department