Your professional partner for safety analyses

We offer you comprehensive consulting in the range of computational analysis and condition assessment for mechanical and plant engineering as well as civil engineering. Our services in the range of mechanical and plant engineering cover all aspects from numerical analysis via fatigue analysis through to fracture mechanics and reliability assessment. Our services in the range of civil engineering include condition assessment of engineering structures. We will be pleased to provide you with personal and individual advice.

The Units in our Department

-

Integrity Assessment and Structural Durability

We offer you numerical and analytical calculations for the static strength and fatigue strength of components in mechanical and plant engineering. We carry out our calculations using both commercially available finite element programmes and our own in-house calculation tools. We apply current standards and regulations to evaluate the fatigue strength. Our field of activity includes isothermal mechanical, thermal and thermo-mechanical fatigue.

-

Reliability and Probabilistic Assessment

We offer you reliability analyses by using probabilistic methods. We mainly deal with topics in the range of life cycle management of industrial facilities (e.g. power and process plants). For your risk-based maintenance and inspections, we carry out complete risk analyses and create corresponding risk matrices for your plant.

Fatigue Testing

Experimental Testing with cyclic loading of material samples and components are used for the determination of design factors. Compression, tension and bending as well as torsion and inner pressure can be applied. Also the impact of environmental exposure (medium, temperature, …) can be integrated in our test results. Stress and strain behavior can be recorded as well as the time- or cycle-dependent redistribution as well as damage development (crack initiation, crack propagation)

Tasks and technical focus

- Numerical analysis of components in mechanical and plant engineering by use of finite element methods (FEM)

- Fracture mechanics calculations of components in mechanical and plant engineering by use of FEM and Xpipe

- Strength calculations and durability analysis

- Numerical and experimental modal analysis of plant components and buildings

- Participation in approval and certification of transport and storage casks for spent nuclear fuel

- Certification according to ISO 9001:2015: “Development and support of databases and software for material laws and life cycle management”

- Review of calculation reports for mechanical design of hydropower plants

- Assessment of components in mechanical and plant engineering

- Review of design and manufacturing documents

- Assistance for quality assurance in manufacturing and operation for machines and plants

- Numerical analysis of fluid-structure interaction for components of mechanical and plant engineering

- Investigation of material and fatigue behavior of steels in the Very High Cycle Fatigue (VHCF) region

- Investigation of material and fatigue behavior of steels at elevated temperatures in corrosive media

- Development of numerical and analytical assessment procedures for components with multiple cracks

- Development of specialized software modules for the assessment of metallic components under quasi-static and cyclic loading

- Investigation of the influence of material parameter uncertainty on the assessment of components

- Fluid-Structure-Interaction (FSI)-test loop

- Mobile vibration analyzer

- Electrodynamic shaker

- Link to High-Performance Computing Center Stuttgart (HLRS)

- Supervision of students (Bachelor, Master studies) by the Institute for Materials Testing, Materials Science and Strength of Materials (IMWF) University of Stuttgart

- Lectures for students by IMWF University of Stuttgart

- Reactor Safety Commission (RSK) Committee on Pressure-Retaining Components and Materials (DKW)

- DGZfP Committee Condition Monitoring (Structural Health Monitoring)

- Certified body according to Pressure Equipment Directive

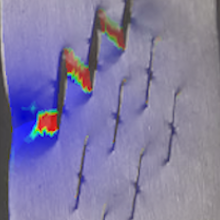

Hollow Section Joints Vibration Test

The video shows the experimental testing of large components using the example of high-strength hollow profile joints with a k-shape and the metrological recording of the resulting strains and deformations.

Flyer of the Department

How to find us

- Our location on campus

Pfaffenwaldring 32 a, 70569 Stuttgart - Open Street Map

Contact

Maximilian Friedrich

M.Sc.Head of Department / Head of Unit