Your professional partner

The Units in our Department

-

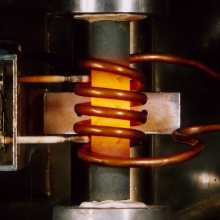

High Temperature Materials Testing and High Pressure Testing

High-temperature materials testing is done to demonstrate the material behavior at high temperatures by adequate experiments. As a rule, time-dependent, inelastic deformation plays a decisive role here. This must be determined by high-precision measurement technology in order to be used as a basis for the adaptation of material models and for evaluations. This includes standard tests under uniaxial, purely static, or cyclic as well as superimposed loading at elevated temperatures. Using unique solutions, which are developed and realized in-house, tests can be carried out on a component level with complex loads from stresses, internal pressures, or bending moments. Our experienced team provides you with comprehensive support for your individual problem, from the development of the optimum measurement and testing concept to the practical implementation and evaluation of the measured data.

-

Materials Modelling

We offer to investigate and elucidate processes and mechanisms in materials on several length scales under loading. The understanding of the interactions between the microstructure and the deformation and damage behaviour enables a reliable estimation of the component lifetime and provides the basis for the creation of „tailored materials“ with desired properties profiles.

Influence of hydrogen

Our autoclave systems provide the possibility to perform mechanical testing of materials and components in water, hydrogen and other atmosphere in a large pressure and temperature range. Our staff members will be happy to provide counseling with regards to determination of test requirements and solutions for providing complex environmental conditions during testing.

Tasks and technical focus

Our department offers a comprehensive range of services in the field of experimental testing and numerical calculations of material behavior. You can find out more about the services we offer here or contact us by phone or email!

- High rate flow properties (e.g. tensile test according to ISO 26203-2)

- Fracture mechanics tests and damage mechanics at elevated loading rates (e.g. ASTM E1921)

- Impact tests on components (drop tower, crash)

- Development, validation and implementation of rate and temperature dependent material and damage models, considering multiaxial stress and Lode angle

- Determination of material parameters for empirical and phenomenological models (Johnson-Cook, Zerilli-Armstrong, Voce, Wierzbicki)

- Numerical simulation of impact events and loadings

- Experimental and numerical simulation of high rate processing (High rate forming, machining and cutting)

- 2D and 3D FE-software for modelling of deformation and damage behaviour in idealized and real microstructures

- Molecular Dynamics simulation software IMD

- Software for 3D microstructure reconstruction based on tomograms and generation of simulation models

- Damage mechanical material models for ductile fracture description (e.g. Rousselier model) and brittle fracture description (e.g. Beremin approach)

- Simulation/network generation and evaluation programs (ABAQUA/CAE,ANSYS,ADINA,PATRAN with interfaces to all common CAD systems

- Access to high-performance computers at the High Performance Computing Centre Stuttgart (HLRS)

We do fundamental and applied research on material behavior to support industrial activities and develop unique solutions to solve your material related problems.

Our activities include:

- Molecular dynamics simulation for the analysis of deformation induced martensite transformation

- Microstructure investigations and derivation of materials parameters relevant for the development of constitutive laws

- 2D/3D-modelling of materials mechanical behaviour based on microstructural effects

- Fracture mechanics at elevated loading rates

- Development of solutions for implementing component tests at high temperatures

- Development and optimization of constitutive laws including damage behaviour

- Generation and optimization of simulation models using the finite element method (FEM)

- Linking of process-simulation and microstructure mechanics

- Verification of the Master Curve Method at elevated loading rates

- Deformation and failure behaviour of thin-walled piping under detonation load

As a part of our corporate social responsibility, we actively participate in technical committees, boards, and panels. Thanks to our independence, we contribute to guidelines and standards with essential findings in research, development, and application.

- Test facility in the Research Association for High-Temperature Steels and Materials (German Forschungsvereinigung Warmfeste Stähle und Hochtemperaturwerkstoffe (FVWHT))

- European-Collaborative-Creep-Committee (ECCC)

- ISO/TC 164 “Mechanical testing of metals”

- ISO/TC 164/SC 01/WG 07 "Tensile testing at high strain rates"

- ISO/TC 164/SC 04 “Toughness Testing”

- German national DIN mirror committees of ISO/TC 164/SC 01 (NA 062-01-42) and ISO/TC 164/SC04 (NA 062-01-46)

- ASTM Committee E08 on Fatigue and Fracture

- NA 062 DIN Standards Committee Materials Testing (NMP)

- NA 062-01-42 AA Working Committee Tensile and ductility testing of metals

- NA 062-01-46 AA Working Committee Fracture Mechanics

- Large component testing up to 2.5 m length up to 700°C

- Large testing machines up to 5 MN

- Corrosion test bench for generating supercritical steam parameters

- Strain-controlled internal pressure tests at high temperature

- Servo-hydraulic High Rate tensile testing machine 100kN up to 20 m/s

- Including temperature chamber -100°C to +300°C, suitable for optical measurements

- Split Hopkinson Pressure Bar apparatus

- Drop towers up to 20 kJ / 10 m drop height

- High-speed cameras up to 2 million frames per second

- Strain gauge amplifier with bandwidth up to 1 MHz

- Force measurement devices for high rate loading

Flyer of the Department

How to find us

- Our location on campus

Pfaffenwaldring 32, 70569 Stuttgart - Open Street Map

Contact

Maximilian Friedrich

M.Sc.Head of Department / Head of Unit

Brian Kagay

Dr.Deputy Head of Department / Head of Unit