Ihr kompetenter Partner

Wir unterstützen Sie gerne bei Fragestellungen zur Tragfähigkeit, Gebrauchstauglichkeit und Dauerhaftigkeit von Bauteilen und Baukonstruktionen. Wir bieten Ihnen durch individuelle Prüfdienstleistungen von der Werkstoffprüfung bis zum Großversuch die Möglichkeit, das Potential Ihrer Ideen oder Produkte bestmöglich auszuschöpfen. Unsere Fachexperten stehen Ihnen zudem für die Erstellung von Gutachten sowie Überwachungs- und Zertifizierungsdienstleistungen nach LBO und BauPVO zur Verfügung.

Die Referate der Abteilung Baukonstruktionen und Bauteilprüfung

-

Lebensdaueranalyse und Ressourceneffizienz

Wir untersuchen die Langlebigkeit von Materialien und Bauteilen unter statischer wie auch zyklischer Beanspruchung. Ein Schwerpunkt liegt dabei auf dem ökologischen und ressourcenschonenden Umgang von Werkstoffen sowie deren effizienten Einsatz hinsichtlich der Trag- sowie Recyclingfähigkeit. Dabei stehen dem Team verschiedenste Prüfeinrichtungen, Messsysteme sowie numerische Software zur Verfügung. Wir unterstützen Sie umfassend bei Ihrer Fragestellung, von der Entwicklung bis zur Prüfung.

Kontaktieren Sie Herrn M.Sc. Martin Markert

-

Massivbau, Verbundbau, Befestigungstechnik

Unser Team steht Ihnen für eine vertrauensvolle Zusammenarbeit für Forschungs- und Entwicklungsaufgaben zur Verfügung. Prüf- und Zertifizierungsaufgaben der Bereiche Befestigungstechnik und des Massivbaus werden als akkreditiertes Prüflabor und als notifizierte Zertifizierungsstelle wahrgenommen. Auch die Prüfung, Überwachung und Zertifizierung von Betonstahl, Betonstahlverbindungen und Gitterträgern gehört zu unserer Kernkompetenz. Schadensanalysen, Bauwerks-In Situ-Prüfungen und gutachterliche Tätigkeiten werden nach individueller Anforderungen angeboten. Gerne informieren wir Sie persönlich über die von uns angebotenen Leistungen.

Kontaktieren Sie Herrn M.Sc Thilo Fröhlich

-

Leichtbau, Metallbau, Fassaden

Unsere Experten bieten Ihnen eine umfassende Beratung sowie Untersuchungen von Fassadenkomponenten und -systemen im Hinblick auf deren Tragfähigkeit und Dauerhaftigkeit. Weitere Schwerpunkte sind Komponenten und Systeme für Unterdecken und Trockenbau. Dabei prüfen wir alle relevanten Werkstoffe, z.B. Metalle, Kunststoffe, Verbundmaterialien, keramische und mineralisch gebundene Baustoffe und Naturstein. Auch die Prüfung, Überwachung und Zertifizierung von Gerüst- und Schalungsbauteilen sowie Baustützen gehört zu unserer Kernkompetenz. Wir unterstützen Sie bei der Erlangung von bauaufsichtlichen Ver- bzw. Anwendbarkeitsnachweisen, etwa allgemeine oder vorhabenbezogene bauaufsichtliche Bauproduktzulassungen oder Bauartgenehmigungen. Wir begleiten Sie zielorientiert über die gesamte Projektabwicklung, d.h. von der Erstellung von Nachweiskonzepten, über die Durchführung und Auswertung von Prüfungen bis hin zur Gutachtlichen Bewertung. Als anerkannte PÜZ-Stelle nach LBO und notifizierte Stelle nach BauPVO übernehmen wir auch die Überwachung/Zertifizierung Ihrer Bauprodukte.

Kontaktieren Sie Herrn Dipl.-Ing. Steffen Keller

Aufgaben und fachliche Schwerpunkte

- Durchführung von Werkstoff- und Bauteilversuchen mit quasi statischer und zyklischer Belastung

- Durchführung von Ermüdungsprüfungen an Materialproben und an Bauteilkomponenten

- Großversuche im 1:1 Maßstab nach Kundenspezifikation

- Zulassungsversuche an Befestigungsmitteln und Fassaden

- In Situ Prüfungen von Bauteilen und Komponenten in Bestandsbauwerken

- Prüfstelle für experimentelle Forschungen an der Fakultät 2: Bau- und Umweltingenieurwissenschaften

Wir sind anerkannte PÜZ-Stelle nach LBO und notifizierte Zertifizierungsstelle nach BauPVO sowie anerkannt beim DIBt für die Durchführung von Zulassungsprüfungen. Von der DAkkS sind wir als Prüflabor und Zertifizierungsstelle akkreditiert. Unsere Arbeitsschwerpunkte liegen in den Bereichen Stahlbau, Bewehrung, Befestigungstechnik, Fassaden, Unterdecken, Betonfertigteile und Wärmedämmverbundsysteme. Informieren Sie sich hier über die von uns angebotenen Leistungen oder kontaktieren Sie uns direkt.

Kontakt: Dr.-Ing. Veit Birtel oder Dipl.-Ing. Steffen Keller

Eingebunden in unsere Dienstleistungstätigkeiten forschen wir für Sie im Bereich der Befestigungstechnik und zu Fragestellungen der Ermüdung von Material und Konstruktion. Wir erweitern unser Anwendungsspektrum für Sie kontinuierlich und sind an verschiedenen öffentlich geförderten Forschungsvorhaben mit unterschiedlichen Fragestellungen beteiligt.

Unsere Forschungsschwerpunkte sind:

- Tragverhalten von Befestigungselementen unter statischer und zyklischer Beanspruchung

- Materialermüdung von Beton, Stahl und Verbundwerkstoffen

- Faserbewehrungen und (geklebte) Verstärkungen für Ingenieurbauwerke

Aktuell arbeiten wir an folgenden Forschungsprojekten:

- DFG Schwerpunktprogram (SPP 2020): Teilprojekt Temperatur- und feuchteinduzierte Schädigungsprozesse infolge zyklischer Druckschwellbeanspruchung

Weitere Informationen finden Sie hier - AIF - IGF: Ermüdungsverhalten randnaher Anschlüsse an Stahlbetonbauteile unter dem Ansatz von Rückhängebewehrung.

Weitere Informationen finden Sie hier

- Auswertung und Beurteilung von Prüfungsergebnissen im Hinblick auf Standsicherheit und Gebrauchstauglichkeit von Baukonstruktionen

- Beurteilung von Bauteilen und Bauwerken nach Brandereignissen

- Bewertung der Tragfähigkeit von Bestandskonstruktionen

- Bewertung von Dübeln zur Anwendung in Beton und Mauerwerk

- Qualifikation, Überwachung und Zertifizierung von Herstellungsbetrieben

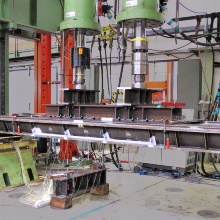

Zur effektiven Abwicklung kundenspezifischer Prüfaufgaben verfügen wir über eine Vielzahl von Klein- und Großprüfmaschinen sowie eine Großversuchshalle mit Spannfeld 6 m x 25 m und variablen Prüfportalen und Prüfzylindern.

- Prüfeinrichtungen für statische Versuche von 200 N bis 15000 kN

- Prüfeinrichtungen für Ermüdungsversuche bis 2500 kN

- Fassadenprüfstand für Windlastversuche

- Fallanlage für Fallgewichte von 500 kg bis 2300 kg und Fallhöhe bis 9 m

- Klimakammern für Temperatur und Feuchte

Wir beteiligen wir uns aktiv in Fachausschüssen, Gremien und Komitees und bringen so als unabhängige Stelle wichtige Erkenntnisse aus Forschung, Entwicklung und Anwendung in Richtlinien und Normen ein.

- Mitarbeit in verschiedenen Sachverständigenausschüssen des DIBt (Bereiche Fassade, WDVS, Befestigungstechnik, Bewehrung und Glasbau)

- Mitarbeit im DIN-Normenausschuss Bauwesen (NABau), Arbeitskreis Befestigungsmittel (deutscher Spiegelausschuss zu CEN/TC 250/SC 2/WG 2; Erarbeitung von DIN EN 1992-4: Bemessung der Verankerung von Befestigungen in Beton)

- Mitarbeit im Deutschen Ausschuss für Stahlbeton

- Mitarbeit in der internationalen fib (fédération international du béton) Arbeitsgruppe TG 2.9: Fastenings to Concrete and Masonry Structures

- Mitarbeit in der Arbeitsgruppe VDI / BV-BS 6205 (Transportanker für Betonfertigteile)

- Mitarbeit im deutschen Spiegelgremium der Group of Notified Bodies

- Mitglied im VMPA

Flyer der Abteilung

So finden Sie uns

- Unser Standort auf dem Campus

Pfaffenwaldring 4D, 70569 Stuttgart - Open Street Map

Kontakt

Veit Birtel

Dr.-Ing.Abteilungsleiter

Steffen Keller

Dipl.-Ing.Stellvertretender Abteilungsleiter / Referatsleiter

- Profil-Seite

- +49 711 685 62206

- E-Mail schreiben

- Abteilung Baukonstruktionen und Bauteilprüfung